【English name】sodium stearoyl lactylate;SSL

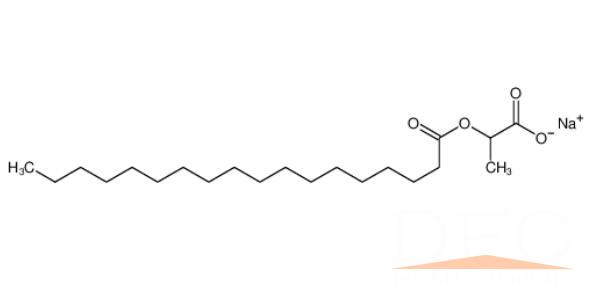

【Structure or molecular formula】C24H44O6Na

【Relative molecular weight or atomic weight】378.52

【Toxicity LD50 (mg/kg)】Rat oral 25000

Introduction

Sodium stearoyl lactylate, the molecular formula is C24H44O6Na, a food emulsifier, prepared by synthesizing sodium salt from stearic acid and lactic acid. It can be added in the production process of noodle products, dairy products, chocolate and various candies, jams, ketchup, sweet noodle sauce and other foods. White to light yellow brittle solid or powder, slightly caramel odor, slightly hygroscopic.

【English name】sodium stearoyl lactylate;SSL

【Structure or molecular formula】C24H44O6Na

【Relative molecular weight or atomic weight】378.52

【Toxicity LD50 (mg/kg)】Rat oral 25000

Traits

Creamy, brittle solid or powder, slightly caramel odor, slightly hygroscopic. During the inspection, a proper amount of sample can be placed in a clean, dry white porcelain dish, under natural light, to observe its color and state.

Application

Sodium stearoyl lactylate has the functions of strengthening, emulsifying, anti-aging, keeping fresh, etc. It is used in bread, steamed bread, instant noodles, noodles, dumplings and other noodle products. It can also be used as an emulsifier in margarine, fresh cream and cosmetics.

1. Enhance the elasticity, toughness and air retention of the dough, increase the volume of bread and steamed bread, and improve the structure of the dough.

2. Make the surface of noodles and instant noodles smoother, have a low rate of breakage, are resistant to foaming and cooking, and are more chewy.

3. The biscuits are easy to demould, the appearance is neat, the layers are clear, and the taste is crisp.

4. Sodium stearoyl lactylate can interact with amylose to delay and prevent food aging and prolong the preservation time.

5. Used in non-dairy creamer, margarine, dairy products and meat products to improve its emulsification stability and application performance.

6. Improve the quality of quick-frozen food, improve the organization structure, avoid surface cracking, and prevent the filling from leaking.

Usage and dosage of sodium stearoyl lactylate

1. Mix the sodium stearoyl lactylate with flour and use it evenly.

2. Add the sodium stearoyl lactylate to 6 times the warm water of 60℃ to make a paste, and then add it to the flour in proportion to the effect.

3. The recommended addition amount is 0.2-0.5% (based on the amount of flour).

Main points of application of sodium stearoyl lactylate (SSL) in bread

1. Application Principle

(1) SSL can form a complex gluten network structure with the gluten protein in the special bread flour, thereby enhancing the gluten and emulsification of the bread products, enhancing the elasticity of gluten and improving the swelling property of the oven. It plays an important role in maintaining the flavor of bread products, especially soft bread. It is irreplaceable for the formation and maintenance of the layered structure of bread.

(2) SSL can interact with the starch in bread flour to prevent and delay the aging of bread. Prevent the transformation of the crystalline form of the matured starch to the aging crystalline form, thereby preventing the deformation and regeneration of the starch. The aging of bread has a serious impact on the flavor of bread products, making its quality worse and even becoming waste products.

2. Addition amount: suggested addition amount: 0.3% based on dry flour, that is, 3 kilograms per 1000 kilograms of flour.

3. Usage: directly add flour to mix, or add to water to disperse, add flour to mix.

Preparation

Method 1: One-step synthesis of sodium stearoyl lactylate (SSL) includes two processes: first polymerization, esterification and then neutralization, and first neutralization and then polymerization, and esterification. After a lot of experimental comparisons between these two processes, it is found that the quality index of the obtained product is better by adopting the synthesis process of first polymerization, esterification and then neutralization. Lactic acid is first polymerized and esterified with stearic acid under certain temperature, vacuum and catalyst conditions to form stearoyl lactic acid, which is then neutralized with sodium carbonate to form sodium stearoyl lactylate.

Synthesis process: first add a certain amount of stearic acid to the reactor, heat and stir to melt, then according to the corresponding raw material mole lactic acid, and a certain amount of new catalyst, connect the condenser tube and vacuum pump, turn on the vacuum pump and condensate water, maintain After a certain degree of vacuum, the temperature is raised to the preset temperature, and then the heat preservation reaction is started. After the heat preservation reaction is completed, the temperature is lowered, and finally sodium carbonate is slowly added for neutralization. The acid value and ester value of the obtained product are measured after drying. Since the acid value and ester value have a greater impact on the emulsification performance and application effect of the product, the acid value and ester value are used as the main indicators to measure product quality.

Method 2: A preparation method of sodium stearoyl lactylate, including the following steps: add lactic acid to water, stir well, then add sodium carbonate, stir at 55~65℃ for 1~1.5h, then add stearic acid and polyethylene diol-400, reacting for 2~3h at a temperature of 160~180℃ and a vacuum degree of 0.07~0.09MPa. After the reaction, the material is discharged. The product is recrystallized with absolute ethanol and dried under vacuum to obtain sodium stearoyl lactylate.

Technical Specifications

APPEARANCE | Cream-colored powder |

Acid Value (in KOH) (mg / g) | 60~80 |

Ester Value (in KOH) (mg / g) | 120~190 |

Total Lactic Acid, w /﹪ | 23.0~34.0 |

Sodium Content, w / ﹪ | 3.5~5.0 |

Plumbum (Pb) / (mg / kg) | ≤2.0 |

[About the label]: Labeling according to requirements, if not required, generally according to the company's internal simple label unified template;

[Sampling]: 200-500g samples are provided for general products, and some products charge a sample fee, and the sample fee will be returned if the order is over RMB 3,000.

[Packaging method]: 25kg/carton for bulk goods, 500g/bag for small samples. Labels can be affixed according to requirements. If there is no special requirement, the labels are unified within the company.

[Transportation method]: Express or logistics, domestic express delivery within 3-5 days, logistics within 5-7 days. Prices generally include domestic transportation costs. International transportation can be FOB or CIF.

DFC Chemical, supply you with best quality of sodium stearoyl lactylate(SSL) & best service!

We also supply calcium stearoyl lactylate(CSL), polyglycerol esters of fatty acids(PGE) and ice cream stabilizer etc.

Contact: DFC Chemical

Phone: +86-13663722676

E-mail: andy@dfcchemical.com

Add: No. 37 Yuxiang Road, High Tech Zone, Zhengzhou City, Henan, China